Guitar modding: how to solder guitar parts

Changing pickups, pots or switches? Keep calm and solder on

Introduction

A lot of guitar mods, like swapping out pickups, involve a fair bit of soldering, so it's worth getting your iron-wielding technique up to scratch.

The best result you can get when soldering is that everything works when the job is done. Neatness is pretty damn important if you want to take pride in a job that’s perfectly executed, with no messy lumps of solder to show you up as an amateur.

Follow our step-by-step guide below and you’ll nail soldering like a pro.

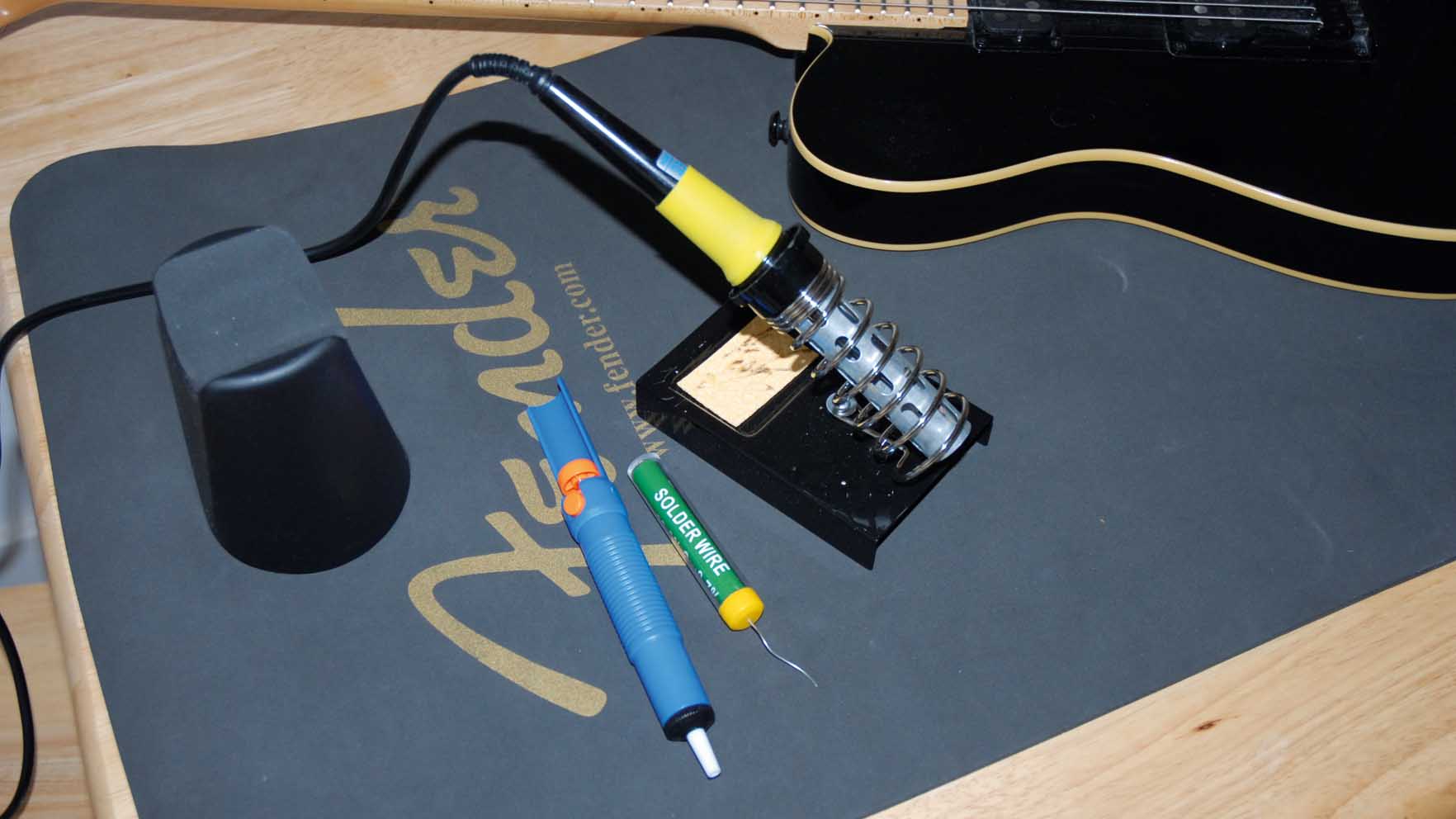

1. Get the gear

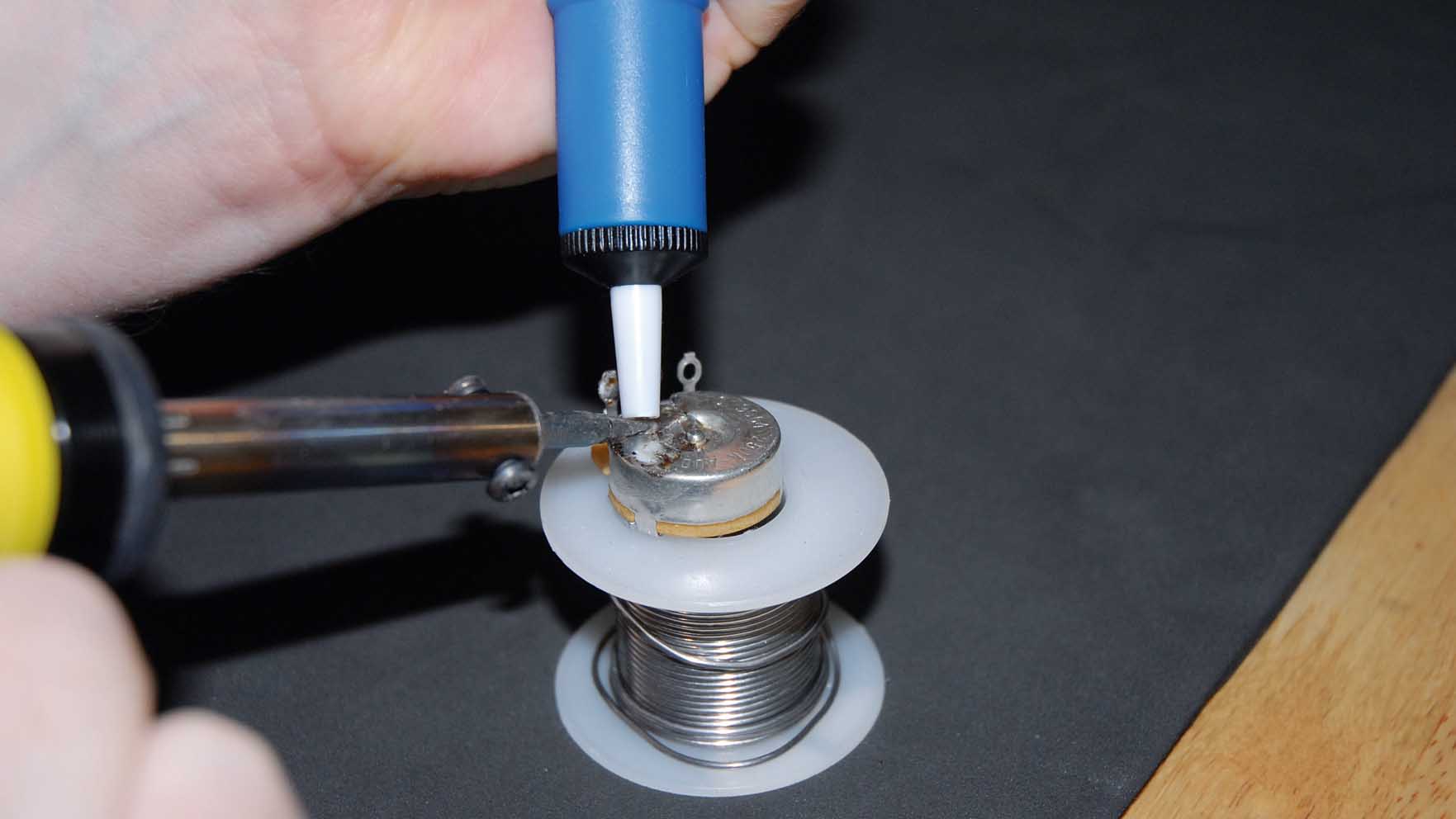

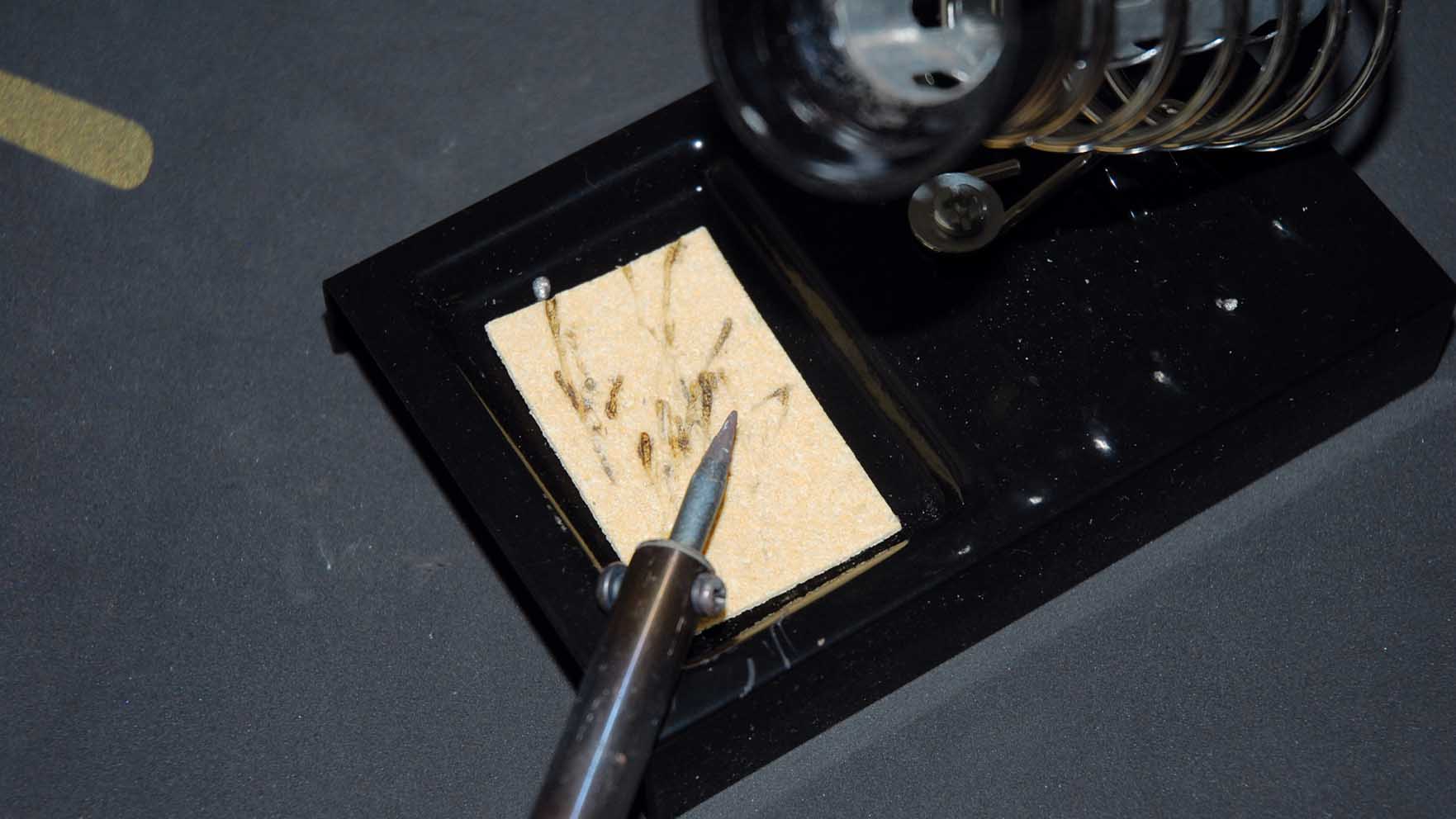

You’ll need a 40-watt soldering iron with a pointed tip, a stand, a sponge, a roll of lead-free solder and a solder sucker. We got the soldering kit above at Maplin Electronics.