The workshop: Seth Baccus Guitars

We head off to Cornwall to meet the man himself...

Seth Baccus built his first guitar in 2004, but by that time, he’d already been part of the guitar industry for seven years, working in Manson’s guitar shop.

His stepfather is master luthier Andy Manson and so Seth’s formative years were set against the background hum of crafting guitars - it’s no surprise, then, he has ended up in his own dedicated facility near Falmouth in Cornwall, turning out some world-class instruments.

If you caught our recent review, you’ll have seen we awarded his Nautilus Classic a score of 4.5 out of 5. It was well deserved, too; the instrument was fabulous in every respect. We paid Seth a visit to find out more about what led him to make instruments under his own name, and discover more about his creative process.

When did the guitar-building bug bite?

When I came to designing my own guitars, I wanted it to pay homage to where I had learned all my skills

“I’d been doing one day a week with Andy while I was at college, and was making the tea, sweeping the floor and generally getting in the way. I always fancied the idea of building a guitar - for myself, predominantly - and, because we used to have to work Saturdays in the shop, my friend and I used to take Fridays off and go out to Hugh Manson’s workshop.

"He would let us have free rein, and we just started putting together guitars for friends, for ourselves - that kind of thing. That’s how it all started. In 2010, I moved to Portugal with my mum and Andy, and we set up a new workshop there. I worked for myself, but next to Andy, for the next eight and a half years. I did my own thing, designing my own range of electrics.”

Working next to someone who was responsible for some very fine acoustic guitars, were you ever tempted to go down the acoustic route?

Get the MusicRadar Newsletter

Want all the hottest music and gear news, reviews, deals, features and more, direct to your inbox? Sign up here.

“Oddly enough, since I moved back to England, we’ve just collaborated on a Nautilus acoustic guitar, which is exactly the same dimensions as my carved top Nautilus, including the depth. So it’s only 50mm depth at the thickest point. We made the first one at the end of last year and it sounded incredible.”

Where do your own guitar designs begin? Does the Nautilus, for instance, owe anything to the Manson legacy?

“Definitely in terms of the outline, that’s a very Manson-inspired outline. Andy has a model called the Bluebird, his very lightweight small-bodied electro-acoustic guitar, which he developed in the early 90s.

"I thought the way the top bout swept into the cutaway was a really elegant line, and it mirrored into the headstock design that he moved onto as well. When I came to designing my own guitars, I wanted it to pay homage to where I had learned all my skills. So it kind of became a reinterpretation of the Bluebird design.

“In terms of the functionality of the guitars, I started with the set-neck design, trying to build the guitar that I’d always wanted but could never find. All my favourite players played Les Pauls, but I learned how to play on a Strat. So every time I picked up a Les Paul, it just felt weird and I couldn’t quite get on with it properly.

"There was something about the response of a Fender-style guitar, with that extra scale length, that the string just responds in a very different way. I thought if you could combine that with the set-neck style, double-humbucking construction, you would get the best of both worlds.”

Best of both

For you, what are the benefits of bringing together the best Gibson and Fender design elements?

“You get all the sustain and maybe the power that you would expect from a Les Paul, but with much more clarity, a much tighter bass response and a sparklier treble. So predominantly my guitars are a 25.5-inch scale length, but with more of a Gibson-esque construction.

"I was always interested in creating timeless instruments - things that are current and not a copy of anything - but that you’re going to look back on in 30 or 40 years and be proud of, and not like, ‘What was I thinking?’ So that comes with the elegance of the outline - to make sure all those lines are harmonious, and it works visually, so that it’ll look good in any decade, in any genre of music.”

Would you agree luthiers look back at the classic designs from major manufacturers and seek to improve them?

I borrow elements from all the classic designs, because they’re tried and tested

“I borrow elements from all the classic designs, because they’re tried and tested. Then I work out if there’s room for improvement, you know? For example, with the tilt-back headstock, if I decrease the angle by two degrees, the join becomes infinitely stronger. A shallower angle is a much stronger join.

"I use a different style of truss rod than Gibson use, so you don’t have to take out anywhere near as much wood at its most vulnerable place. Over and above that, I take a lot of time over my fretwork to make sure it’s absolutely spot-on because it can really make or break a guitar, that level of detail.”

Just looking at the Nautilus, it’s clear to see finishing is a top priority...

“It’s all very well spending hours selecting mahogany bodies or whatever, but if you don’t finish it off with all the right bits and pieces, you lose that quality. I always say a great guitar is a combination of a thousand tiny details at every single stage, all the way through. ‘What’s the best way to do this? What’s the best way to do that?’ If you ask those questions all the way through, and keep your integrity, you’ll end up with a great instrument.”

When it comes to sourcing hardware for your instruments, are you equally as meticulous, only using the very best components available?

“Yes, definitely. It’s a mix-and-match situation. Who’s making the best tune- o-matic bridges, you know? For years I’ve been using the TonePros stuff with the brass saddles. I’ve just started using some of the ABM stuff, which is German- made, and it’s slightly different to the TonePros in the fact it’s milled out of solid metal, rather than die-cast, which I think can only be a good thing.

"They do some variations: an aluminium, a brass and a steel version, which will sound slightly different, so you can tune them to a particular instrument. I use the finest tolerance CTS pots that I can get my hands on. I use Gotoh machineheads as tuners on everything, unless the customer specifies otherwise - they’re superb.

"So, yes, it’s exactly that: quality and attention to detail. The quality of the bone for the nut material, that’s something I only buy from one supplier as it’s always superb.”

Timber time

How do you go about selecting the timber for the instruments?

“All my ebony comes from one place in Spain. It’s always superb quality, I know it’s FSE-certified, Rainforest Alliance certified, so it’s all contributing towards sustainable forestry, and the quality is reliably excellent. I don’t have to be there picking it out individually by myself - I know it’s going to be high quality.

I think we’re actually living in a golden age of guitar making right now

“I have a couple of maple suppliers, one in the US and one in Europe, depending on what kind of maple I’m looking for. Mahogany is a bit harder, because the quality of it varies so wildly these days; you really have to buy from someone you have a relationship with.

"You can be quite specific about what you want and they’ll know the level of instrument that you’re trying to build and what’s acceptable and what’s not. It’s not always a reliable supply chain.

"You might find someone who, for two years, had an amazing stock of mahogany, and then it’s all gone and they can’t get it anymore. Then you’re back to square one, you know? But I’m coming up to my 10th year of full-time guitar-making now, so I have quite a nice network dotted around the world of people I trust and that I can buy from.”

What other designs do you have on the drawing board at present?

“I’m developing a few new models at the moment. There’s the more Fender-inspired Jazzmaster-type models, which have a very different kind of sound and style to them as well. I also have a Telecaster base type model, which has been pretty popular, too.” Do these designs follow the familiar Fender route with bolt-on necks and alder, ash and maple tonewoods?

“Ash, maple, alder, all that kind of stuff. You get something so different with a bolt-on neck than you do with a set neck. I’ve completely fallen in love with the whole bolt-on thing, all over again. It has got such a unique attack and snap to the string that it has really engaged with me in some way, you know? I’ve really enjoyed doing those. With a maple neck, you know roughly what you’re going to get. It leaves room for experimentation, as well.

“I recently built a bolt-on guitar that had a mahogany neck and a mahogany body, but it was a bolt-on with six-a-side headstock. That was quite interesting, because it’s combining the two material choices of a set neck but building it in a bolt-on style.”

With a growing reputation as a first-class builder, what do you think the future holds for your business? Are there any plans for expansion?

“I’m lucky to have plenty of work on at the moment. I’m also in the process of taking on a member of staff, coming in two days a week at the moment. We’re both working towards making that more full time. Eventually, I would love to have a small team of people, all working together, developing and refining the guitars that we’re building.

“I think the handmade artisanal market is very lively at the moment and I’ve often said that I think we’re actually living in a golden age of guitar making right now.

"Never in history have you been able to buy as many great guitars as you can now. There are so many wonderful makers and artists out there producing fantastic stuff, which is all very inspiring. It keeps you on your toes and pushes you in new directions. Exciting times.”

“Its mission is simple: unleash the power of any amplifier or line-level source without compromise”: Two Notes promises a “watershed” in tube amp control with the Torpedo Reload II

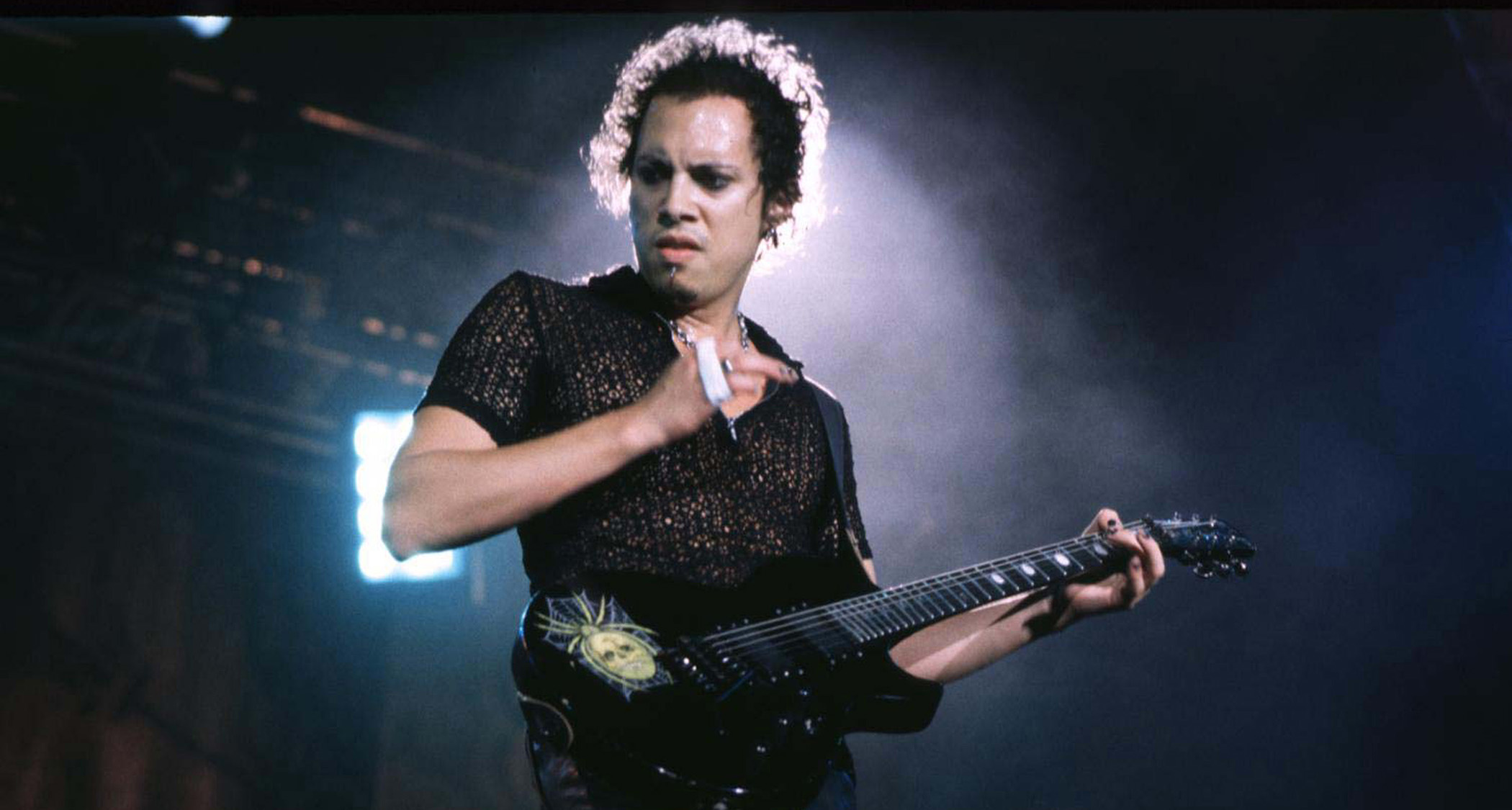

MusicRadar deals of the week: Enjoy a mind-blowing $600 off a full-fat Gibson Les Paul, £500 off Kirk Hammett's Epiphone Greeny, and so much more