The evolution of Yamaha's Revstar guitar range

Exclusive pics and behind-the-scenes access

Introduction

As fly-on-the-wall observers, we have had exclusive access to the evolution of Yamaha’s new Revstar guitars. It’s been quite a ride…

It’s 50 years this year since Yamaha entered the electric-guitar market and, although it wasn’t a pre-planned celebration, the new 2016 Revstar guitars are the result of the longest and most expensive development of any Yamaha electric throughout that half-century history.

Guitars don’t just make themselves and to find out how the project had moved forward, we went to Yamaha HQ in Hamamatsu, Japan

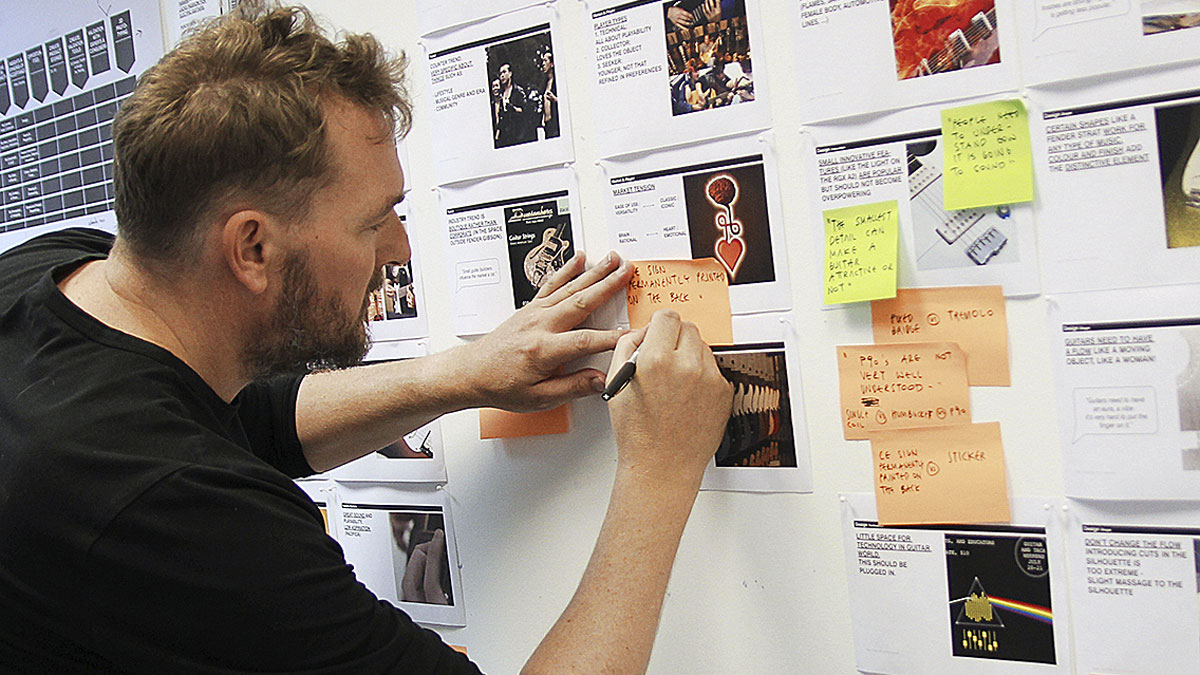

Our story starts some three years ago, when we were summoned to the offices of south London-based design company, forpeople, to observe some new guitar designs.

Expecting to see prototype instruments, we were surprised to see, instead, design concepts reflecting both Yamaha’s long history of guitar design married with broader concepts of contemporary Japanese youth culture alongside a motorcycle inspiration - Yamaha started making motorbikes back in 1955 and is now one of the world’s leading manufacturers. Invited experts, including dealers and players, were simply asked their opinion on the concepts and the 2D instrument renderings.

Some months later, we were invited to a second evaluation session. This time, the concepts had been honed and, again, the invited VIPs gave their thoughts. Of course, these evaluation sessions weren’t just limited to the UK, but it was becoming more than obvious that whatever it was that Yamaha planned to come up with, it was in it for the long haul.

Yamaha’s guitar product planning manager, Julian Ward (essentially the director of the project), confirmed this saying, Yamaha’s “long-term strategy is to genuinely get back into electric guitars. Maybe our next step will be different, but this is the first new design since the AES620, and that was some 10 years ago.”

Fast-forward to the NAMM show 2015 and, some two years into the project, we actually get to see some actual guitars, albeit in a hotel room. It’ll still be a year away until they’re launched to us guitar players, but this slow filtering of hugely diverse design inspiration and opinion was clearly working.

Behind the scenes, of course, Yamaha’s design and engineering teams had been burning the midnight oil. Guitars don’t just make themselves and to find out how the project had moved forward, we went to Yamaha HQ in Hamamatsu, Japan.

Just different enough

If forpeople’s designers had no specific experience in instrument design, we were surprised to learn that the primary designer of the new guitars, Piotr Stolarski, was also an instrument-design ‘virgin’.

Clearly, he wasn’t Japanese either, joining Yamaha from his Polish homeland only a little while before. We learn, too, that what was to be called Revstar was his first job for his new employers and that it was only after we had visited that he realised it might be quite a big deal.

It seemed like it was a younger brother of the original Yamaha SG and that’s a big part of our electric-guitar history

“We had to change the way of thinking,” muses Piotr, reflecting on the design process. “We didn’t just want to think about the guitar; we wanted to consider it as a design project. To me, as a designer, lots of guitars seem to be created by trying to make the ‘perfect’ instrument in the taste of the sole maker.

“Our process was a lot more democratic. The main problem we faced was to create something original but not freakish - people want old guitars, they don’t want new guitars.”

But if that was the sole case, there are plenty of old designs in Yamaha’s 50-year electric-guitar-making past that could surely have been reissued.

“No, this is part of our future,” states Julian Ward emphatically. “Not a reissue of our past. But that’s not to say the new design couldn’t be the guitar we never made, for example, in 1973…”

Piotr flicks through pages of sketches before finding what he is looking for: the first rendering of what was to become Revstar. It’s surprisingly close to what we now see as the RS502T.

“Some people suggested it should be a bit more Jazzmaster, a bit more Telecaster… but it seemed like it was a younger brother of the original Yamaha SG and that’s a big part of our electric-guitar history. Some of the other designs I really liked,” laughs Piotr, “but it was decided they were too niche.”

Not another guitar

In truth, Yamaha was more than aware that the last thing the world needs was just A. N. Other electric guitar.

Senior designer Toshihide Suzuki reaffirms that the underlying concepts for the design were twofold: to express ‘Yamaha-ness’ and ‘Japanese-ness’. Then there was the Café Racer inspiration from forpeople that remains at the heart of the Revstar concept:

It might also be surprising, especially with the intent of displaying ‘Yamaha-ness’, that the Revstars don’t display a Yamaha logo

“A classic guitar that we’ve tuned up,” interjects Piotr by means of explanation. “For example, the pickguard: it’s cropped, cut in - totally inspired by the Café Racer. Also there’s the raw materials, an engineering inspiration, beautiful details… the beauty of a specific part.

“I designed the tailpiece,” he continues. “It was about customising. Originally, the idea was to have the strings anchoring through the body or to attach them to the tailpiece, like a convertible. So, the final design is adjustable - higher or lower - but not string-through.”

Typically, it’s function and beauty combined - all part of the ‘Japanese-ness’: “It shouldn’t just be for decoration,” concludes Piotr.

It might also be surprising, especially with the intent of displaying ‘Yamaha-ness’, that the Revstars don’t display a Yamaha logo - apparently the first Yamaha electric guitar not to do so, though they do have the simple Yamaha tuning-fork logo on the headstock.

“This is not about hiding,” Julian says of the design decision. “We should celebrate the Yamaha-ness, but not having the logo was not about being Yamaha, but about being right for the guitar. From a branding point of view, via the tuning fork logo, it says ‘Yamaha’, but in a cooler way.”

Design to engineering

With the concepts all in place and a strong idea of what the new guitars were going to be by the tail-end of 2014 - there were in fact two distinct prototyped designs at this stage: what we now know as Revstar, designed by Piotr, and another by Toshihide - the project slowly edged forward.

With the decision made to focus on the Revstar design in early 2015, the project entered the real world: how they were actually going to be manufactured, the precise materials, parts, the engineering drawings… on it went. Of course, at this stage, thoughts about the final retail pricings had to be brought into the instruments’ specifications, too.

You see, most players are happy with their Fenders and Gibsons, so we always ask, ‘Where does Yamaha fit in?’

To take us through some of the decisions, we’re led into a large concert hall at Yamaha HQ where the whole Revstar range is assembled, as well as the key members of the engineering team. It’s the first time we see the fruits of nearly three years’ work and we’re impressed by the diversity of the final models.

“The project was easier than some,” says engineering manager, Kiyoshi ‘Jackie’ Minakuchi. “We had a very clear design concept. In the past, that wasn’t always the case, but with the ‘Café Racer’ concept, we could imagine what the guitars should be. You see, most players are happy with their Fenders and Gibsons, so we always ask, ‘Where does Yamaha fit in?’”

“We fight with price, too,” continues Jackie, “and obviously, with the lower price of the 320, it has the most basic specification. We might have the standard-spec humbuckers from our vendor, but the Café Racer concept suggests, well, it’s not a big heavy bike - it’s a lighter weight, easier to manage, so the pickups shouldn’t be too heavy sounding.

“So, on the 320, it’s still a high-output humbucker, but it’s balanced sounding, not aimed at a specific genre. It’s a ceramic-loaded pickup and we went through some 50 prototypes before we were happy.”

420 time

Next up, Jackie shows us the 420, which adds a 5mm maple cap that Jackie believes adds to the sound making it a little “harder and more defined”. Along with its belly cut, bound fingerboard edges and chrome-plated knobs, the covered pickups here differ from the 320s with Alnico magnets:

We didn’t want it to be unusual: it has to be something that the player is used to

“They have a pretty similar specification, with a slightly brighter tonality,” adds Jackie. The 420 also introduces the so-called ‘Dry Switch’ circuit:

“It’s a simple passive circuit [one resistor and one capacitor] that acts as a low cut [a high-pass filter],” explains its designer, Hirotaka Niiro. “It’s not a real ‘single coil’ sound. The advantage over a traditional coil-split is that, in both modes, it remains humbucking.”

“We had been experimenting with various circuits,” continues Jackie. “We started with a passive booster on the bridge pickup, but with the Revstar project, we forgot about that; we didn’t want to confuse our customers.

“So, we looked at ways of making a ‘single coil’ sound from a humbucker in a simple, single function. We didn’t want it to be unusual: it has to be something that the player is used to.”

Tech specs

The 502, like our reviewed 502T, stays with the all-mahogany construction with a maple cap. “But the difference is that the top is slightly carved, adding a forearm contour. We have a bound fingerboard and satin nickel hardware as opposed to the bright chrome of the lower number models,” explains Jackie.

We also have a satin finish to the top, which is all part of the Café Racer concept

“We also have a satin finish to the top, which is all part of the Café Racer concept. We actually use steel wool to cut back the [gloss] finish on both the front and the headstock face.”

Of the 502’s P90-style soapbar single coils, Jackie honestly reflects that he “wasn’t a big fan, to be honest. But we found a good recipe from our prototypes. Now, it’s my favourite! It’s close to, for example, the Seymour Duncan SP90-2 high-output soapbar, but with Alnico magnets.

“We’re using heavy Formvar-coated wire for the humbuckers for a slightly brighter ‘open’ tone but on the P90s, we’re using plain enamel-coated wire for more of a solid, cut-through sound.”

Aside from its gloss top, the 502T is a close cousin to the 502; the most obvious difference is that tailpiece and its tune-o-matic-style bridge - very close to the original Revstar concept rendering.

“The tailpiece is cast aluminium,” says Jackie. Four bolts hold it in place and the top two are sprung, so you can actually use it as a [pitch rising] vibrato and you have a choice of setup.

Lowering the tailpiece behind the bridge increases the back angle, and Jackie believes this “creates a slightly tighter bass response”. Raising the tailpiece - reducing the back angle - creates more of a ‘trapeze’-like sound: brighter and ringing.

Slow burner

“We didn’t really like the original rendering of this guitar,” offers Jackie, “but it had such a good response from all the various evaluations we had, we had to change our mind. It has a sort of Gretsch character.”

Initially, internally at least, it seems almost no-one liked the 502T. But Jackie admits, “I like it better now - I’m actually very proud of this guitar!”

The 502T was the model we’ve had most discussion about. Do we really need it, or is it a designer’s folly?

“It’s true,” reinforces Julian. “It was the model we’ve had most discussion about. Do we really need it, or is it a designer’s folly?”

The 620 seems a safer bet. Essentially, it’s the same as the 502, but with humbuckers and flame-maple top (maple veneer over soild maple). Again, the top and headstock face are steel-wooled.

“It features superior-grade versions of the 420 humbuckers with satin nickel-plated covers,” says Jackie, who then points to the different inlays, inspired, he says, by the early 70s Yamaha SF700 - sort of dual split parallelograms. The 720B is basically a 620, but with a licensed Bigsby vibrato creating a different look and sound - not least from its more Gretsch-looking pickups.

“I didn’t know too much about this style of pickup,” admits Jackie. “It has fewer turns - around half - so it’s got a lower output; we added two Alnico magnets stacked underneath. It has a pretty bright tone - not as bright as a TV Jones - but with power and with more bass response. We also have locking tuners on this model.”

Plugging in

The final two models, the 820CR and P20 Pro, look very similar, but the latter is made in Japan, not Indonesia like the other models.

The 820 is like the 502, but with a satin nickel TonePros wrapover bridge and two humbuckers, while its pickguard is a coppercoloured anodised aluminium.

In early November, we attended the premiere of Revstar at London’s iconic Abbey Road studios

Plugging in the Pro version after the 820, there’s a noticeable difference in the quality of sound and the resonance. “It’s essentially the same guitar,” says Jackie, but with aged pickup covers and an unplated copper pickguard, along with black Tusq nut.

It’s the only model to include a hard case and also employs Yamaha’s IRA (Initial Response Acceleration) that simulates hours of playing “and gives a ‘played in’, mature guitar from day one”, states Yamaha’s explanation.

Just as we go to press, however, Yamaha tells us it’s suspending the release of the Pro until later in 2016. Internally, it seems the company is unsure whether it’s different enough to the 820, bearing in mind its cost would be higher, around £1,200. Ah, well…

In early November, we attended the premiere of Revstar at London’s iconic Abbey Road studios. The final marketing materials were all in place - although the final pricing is still being hotly debated - and we can reflect on what has been quite a journey.

We have no idea if Revstar will be the success Yamaha hopes. Only time will tell. One thing’s for certain, though: it won’t be for the lack of trying.

Dave Burrluck is one of the world’s most experienced guitar journalists, who started writing back in the '80s for International Musician and Recording World, co-founded The Guitar Magazine and has been the Gear Reviews Editor of Guitarist magazine for the past two decades. Along the way, Dave has been the sole author of The PRS Guitar Book and The Player's Guide to Guitar Maintenance as well as contributing to numerous other books on the electric guitar. Dave is an active gigging and recording musician and still finds time to make, repair and mod guitars, not least for Guitarist’s The Mod Squad.