Gibson Memphis factory tour

We take a look at where the magic happens

Gibson Memphis factory tour

Gibson is perhaps the most loved guitar brand of all time, remaining at the centre of guitar players’ dreams and popular music history since the 1930s.

Always innovating, often controversial, what may look like a giant, impenetrable corporation from the outside is in fact a collection of smaller specialities and subcultures, fuelled by a deeply passionate staff of artisans and craftspeople who, regardless of position or function, remain fiercely proud of what they do.

The company has grown confidently ever since the much-written-about management buyout of 1986, as has its need for production capacity. Its first specialist offshoot was Gibson Montana, which began building flat-top acoustics in 1989. Next came Gibson’s Custom Shop in a separate Nashville facility in 1994, and today we’re visiting the most recent ‘new’ factory, around 200 miles away in Memphis, where Gibson guitars have been rolling off the line since 2000. 2013 is significant, however, because it is the year Gibson Memphis has officially become its own division.

Meet David Winters...

David Winters has been with Gibson ever since 1986 and today he is general manager of the Memphis facility.

“We do all the guitars here with f-holes that wouldn’t be a carved top, like an L-5 or Super 400,” he says as we begin filling in some background.

“We built the facility from the ground up and we focus primarily on the ES-335s, 175s, 330s, 339s... anything with a laminate, semi- hollow body, including Lucille!”

Workin' in Memphis

It’s fitting BB King’s guitar is made here...

“Memphis is really the crossroads for the blues. Clarksdale, Mississippi is just south of here, the Blues Highway is [South] 3rd Street that runs right through the city, and we’re just a block off Beale Street – what better location to be for blues and jazz?

"We’re so close to Nashville [Gibson’s HQ], yet they’re two completely different cities with two completely different cultures.”

Making the tops

Some ES guitars are still built in the Custom Shop in Nashville, though, right?

“Yeah, when they were originally doing the [Historic Series ES-335] ’59 and the ’63 there, this facility was so much younger that we didn’t really have the expertise to do a true, true historically correct instrument.

"Over the past several years, however, we’ve really focused in on the details and now we’re capable of building those historically correct ES-style instruments.”

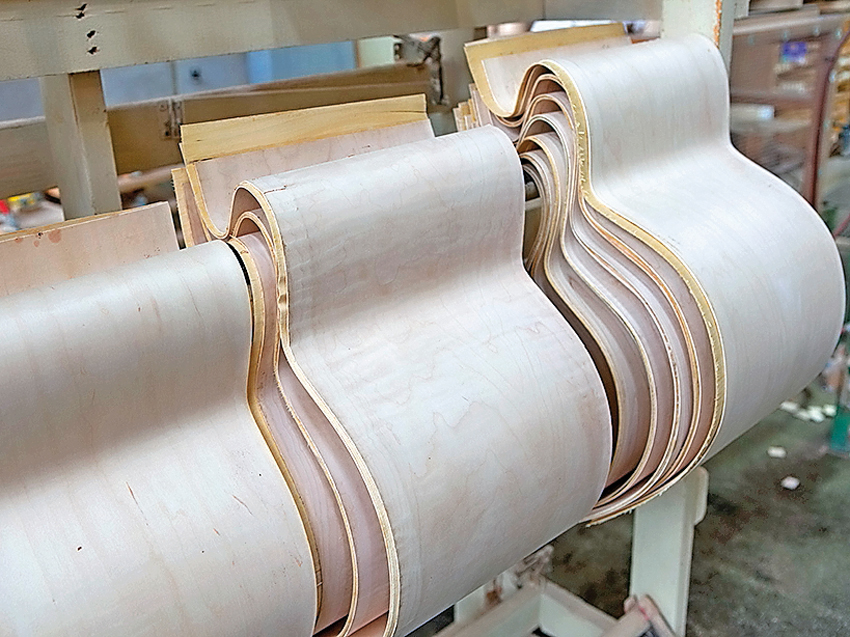

Pressing laminates

How many people work here in Memphis?

“81 directly, then we have a peripheral staff of about 12 – support staff in things like engineering, buyers, schedulers, accounts, shipping... things like that.”

And how many guitars do you make here?

“65 a day, that’s up around 25 a day from where we were at the beginning of the year.”

Back plate

There’s so much hand work happening in production. How do you maintain quality control with such a high level of individual human judgement in so many areas?

“We have inspectors throughout, but before that, at those critical workstations we have examples of what each part should be.

"We try to achieve that consistency both through continuous training and also continuous monitoring. A lot of it still ends up in the hands of the operator paying attention and being trained properly.”

Rims galore

If we take just one aspect – let’s say scraping the binding back after finishing – how long does it take to train someone to do that?

“Oh, it can take anywhere from one to three months for somebody to become proficient at it. Some people pick it up quicker, obviously, but it is a very detail-oriented job that takes finesse. The only gauge is a visual gauge – it’s totally hand-done.”

Attaching centre blocks

Presumably some areas lend themselves better to mechanisation?

“Over the years we’ve developed tools for different areas. Sometimes it works and sometimes it doesn’t, because sometimes there’s just no better way [than hand work]. But a prime example is that for quite a number of years, fret-levelling was always done by hand, until the invention of the Plek machine.

"Now that does a complete scan of the neck and comes in and looks for detailed inconsistencies: a piece of equipment that does a great job. It’s a quality enhancer – a guitar that’s been Plek’d plays better than one that hasn’t.

Adding tops and bottoms

“But a lot of it just has to be done by hand: cutting the binding back, rolling the binding in...

"Y’know when somebody picks up a guitar, the first thing they do is they put it in the playing position and they feel the neck. They run their hand up that neck; getting that feel right has to be done by hand.”

Binding channels

Has Gibson always made its own laminates for ES-style bodies?

“Each model has its own spec and shape, the important thing is having all three pieces of wood [for the laminate] with identical temperature and moisture content.

"So we bring the wood in and we let it equalise, because when you glue those three pieces together, they have to be pretty exact as far as humidity and moisture content are concerned."

Wrapping the binding

"So it equalises the wood at the same time when you heat it and cool it like that with the glue; it helps it hold its shape. We can control the quality by doing that in-house.

"You can see the original press in the factory. It’s from the early 1940s, we think. It’s pressed nearly every laminate guitar Gibson has done since the 1940s: a pretty remarkable piece of equipment.”

Bound for glory

With the explosion of knowledge online – whether it’s correct or not – you guys are under more pressure than ever to get those tiny details right. Do you feel that?

“Yeah! The internet has been a good and a bad thing. It’s provided a lot of knowledge to a lot of people who otherwise wouldn’t be exposed to it. And not only with guitars, of course: everything.

Neck pocket routing

"At the same time, it’s allowed people with bad information to have a voice, so there’s a lot of misinformation out there as well.

“When you actually look at guitars from the 1950s and earlier, there was quite a bit of variation. Back then there was even more hand work done to the guitars, so it was even harder to control."

Neck adjustments

"There were not only a lot of inconsistencies from a materials standpoint, but also from a dimensional and workmanship standpoint.

"There were some beautiful guitars made back in those days, and those are the ones we try to emulate. A lot of those guitars have what we like to call the ‘mojo’ – tone, feel, history – they really push us to keep getting better and achieve that mixture of wood and paint and lacquer and electronics and hardware for that optimal tone.”

Shaping the neck

Do you use any modern methods for examining old guitars?

“Recreating those instruments is quite the undertaking, so yeah, one example is this gentleman by the name of David Carpenter out in Washington State who not only has a collection of great guitars, but who also has friends in the medical industry.

"They’ve taken guitars and put them in MRI machines to measure densities of materials... all kinds of exact measurements. So he’d take his original guitars to his doctor, and the next day I’d get an email...

Hand sanding

“We’ve found some interesting things; that’s where you find a lot of the variances in the guitars over the years.

"For example, we found original ’59 335s that had head and tail blocks on the centre block, which you rarely see. Most of ’em we’ve seen have been single pieces.

"You find those nuances. It’s a guessing game. If you look at the original blueprints, it called for a solid centre block, but maybe they had limited materials available to ’em, so they made what they made out of necessity.”

Finishing

Will other guitars ever be made here?

“There are no immediate plans to move other guitar production to Memphis. There’s always the goal every year to design new models and/or recreate ‘new’ old models – like the ES-330s and the 295 we’re doing this year – or we make adjustments to current models.

As we get feedback from dealers and consumers we’re finding out what people prefer. We value feedback from experts, dealers and, of course, consumers because those are the people who fork over money. But the true gauge is what sells, and that’s where we try to focus.”

Scraping the binding

How do you approach the development of a new model?

“We always shoot for new, innovative product. The ES-139 and the 195 this year, they have some features you might find on historical guitars, but as an example the 390 over there [points to a new, small-bodied single-cutaway thinline with no f-holes], that was based off of the ES-330, being hollow, but you never know what it’s going to do when you shrink body sizes and make changes to hardware and pickups: it’s purely experimental.

"When we build prototypes, we’ll run them past some people to get feedback out in the market; we can’t just put Gibson on the headstock of anything and expect it to sell. The guitar market is competitive, so being innovative and coming up with new products is a prerequisite for each division every year.”

Buffed to a finish

Gibson is often criticised for some new products – the Firebird X is a good example – being ‘too innovative’ or ‘out there’, but it’s always been that way, hasn’t it?

“The Flying V and Explorer? Those were pretty radical shapes back in the 1950s. They didn’t sell real well back then, but they’re now staples in the guitar industry. They were the Firebird X of their time.

"Yes, you catch some grief about it, especially from the purists, but the innovative guys understand what we’re trying to achieve. We stay focused and do what Gibson has done best for years, but we also have to lead. If we don’t, somebody else will!”

VOS process

Many of us like our guitars to exhibit the time-earned elegance of a vintage original, but tend to wince a bit at serious wear and scratches on a new instrument.

Gibson’s VOS process is exactly that: a fully finished guitar made to look ‘old’ with a special combination of finish and hardware treatment. Approximately 30 per cent of Memphis-made guitars are VOS.

“We have a lot going through,” explains Mike Voltz. “They’re very popular in the market right now: through the roof!”

Rather than physically chip and ding the guitar, Gibson instead opts to dull the nitro- cellulose finish back just slightly, while also tarnishing the various hardware and other components, using a series of closely guarded techniques, materials and chemical treatments.

“The idea is that maybe the guitar got played for about three months or so,” continues Jim Lillard, manager of final assembly, repair and VOS hardware processes. “Then it went back in the case, [got] put under the bed and forgot about. During that time, the lacquer – solvents – will evaporate inside the case that produces a kind of haze.

VOS fittings

“Tailpieces, tuning gears, bridges, and various other metal parts are aged in acid,” continues Lillard. “We get the effect that parts would have from oxidising naturally.

“On a Bigsby we also have to scrape the black paint off the patent number. The way they come now, the only thing that’s exposed is the ‘Bigsby’ part: it all takes time and extra attention.

“The other parts, we have to rust: pickup polepiece screws, strap buttons, screws...”

Lillard goes on to explain how Gibson’s ageing processes need constant refinement. “[Parts] manufacturers are trying all the time to frustrate what we do with the ageing,” he laughs. “Nobody wants to see their products all tarnished and aged; they want it to look shiny as long as possible!

"Like these [new] strap buttons. They’ve switched something so they don’t age as well, so I need to come up with some new tricks!

“As for the plastic parts, the knobs are wiped with an oil to give it that finger-funk kinda feel: we do it all right here.”

And it's done...

Gibson Memphis is turning out some amazing guitars in the best traditions of the brand, and if you're a sucker for an elegant semi-acoustic then you're no doubt GAS-ing pretty hard right now.

To check out the guitars currently coming out of Memphis, check out the official Gibson website.