The Workshop: How to clean your drum hardware

In ten easy steps!

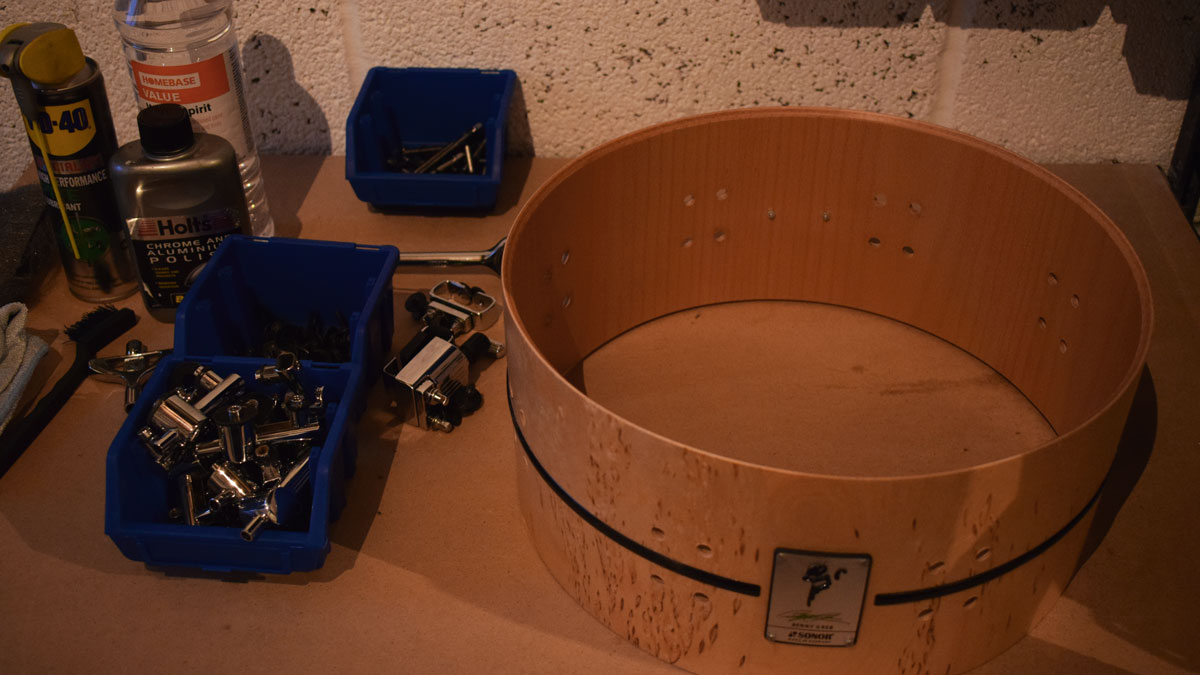

1. Prepare the workstation

If you’re anything like us, you’ll like taking apart your bits and pieces of drum gear, either to see what makes it tick or to sort out a squeak or rattle. Makes a mess and we usually forget which bits go where.

Still, from time to time, it is a good idea to strip down your drums and give them a good going-over. By following our step by step guides to gear maintenance each month, you’ll soon have your gear tip-top. in this month’s workshop, we guide you through the simple process of removing your shell hardware and bringing it back to its former glory.

For this simple job you will need: a polishing cloth, metal polish, a screwdriver or cordless drill with the correct bit(s) and some containers to organise your removed parts.

Optional extras include fine wire wool, your choice of lubrication, a small brush and some white spirit. Of course, don’t forget your drum key.

2. Remove both heads

Evenly de-tune and remove the tension rods, setting them to one side. Soaking the rods in white spirit is a great way of stripping any old grease away and leaving them fresh.

Next, remove the heads and rims from the drum shell. This is necessary in order to access the fixing screws of the lugs.

4. Remove the lugs

Take the lugs off completely and set to one side; paying particular attention to the order in which the fixings fit together.

It is not uncommon for there to be a spring or a rubber gasket fitted between the shell and its hardware, so make use of your containers, keeping everything where you want it.

5. Clean the drum

With the shell stripped down, now is a perfect opportunity to give the drum shell itself a quick once-over.

It is not necessary to use any cleaning agents, just rubbing with a clean dry cloth will work. Although, drums with a wrap or lacquer finish will benefit from a polish with something like Pledge.

6. Clean the hoops

If your hoops are particularly dirty or even showing signs of rust, this is where you will want to employ the wire wool.

In most cases though, we usually reach straight for the metal polish. Apply with one corner of your cloth and buff away with the other, leaving your rims looking as good as new.

8. Clean the tension rods

Once you have finished with your hoops and lugs, you can turn your attention back to the tension rods that have been soaking in white spirit.

Before drying them off, give them a twist in the wire wool to clean any gunk out of the threads. You may chose to re-apply some lubricant at this point.

9. Re-attach the lugs

Replace your shiny new lugs, ensuring that you replicate the order of the parts as before.

For instance, this Sonor snare has rubber washers which should sit between the shell and the lug.

Gently fit the lug back into position, hand- tightening the screws at first, then finishing with your drill or screwdriver.

Tom is a professional drummer with a long history of performing live anywhere from local venues to 200,000 capacity festivals. Tom is a private drum tutor, in addition to teaching at the BIMM Institute in Birmingham. He is also a regular feature writer and reviewer for MusicRadar, with a particular passion for all things electronic and hybrid drumming.